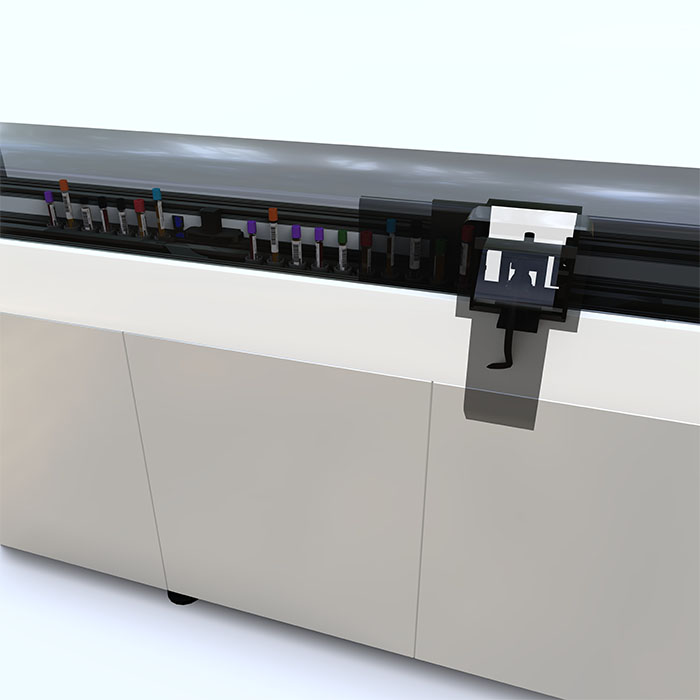

Pre-analytical Modules

From the check-in step, samples are prepared for the right analyzers

FlexLabTM’s powerful workflow automation software drives every single clinical sample along its most efficient path, stopping it only where needed, and preparing it for the tests in the assigned analyzers.

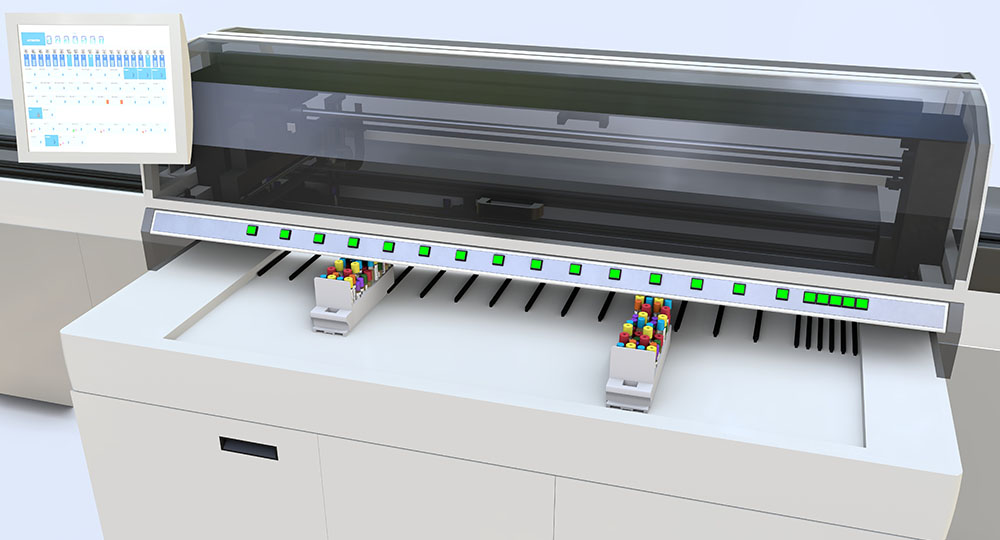

Aliquoter Module (ALQ)

Generates secondary sample tubes, aspirating a configurable sample volume from primary tubes to perform multiple analyses using a single primary tube. Aliquoter throughput: up to 500 tubes per hour.

Centrifuge Module (CM)

Automates the centrifugation process, with the option of easily setting all operating parameters. Blood samples are balanced through weight checks. Throughput: up to 300 tubes per hour.

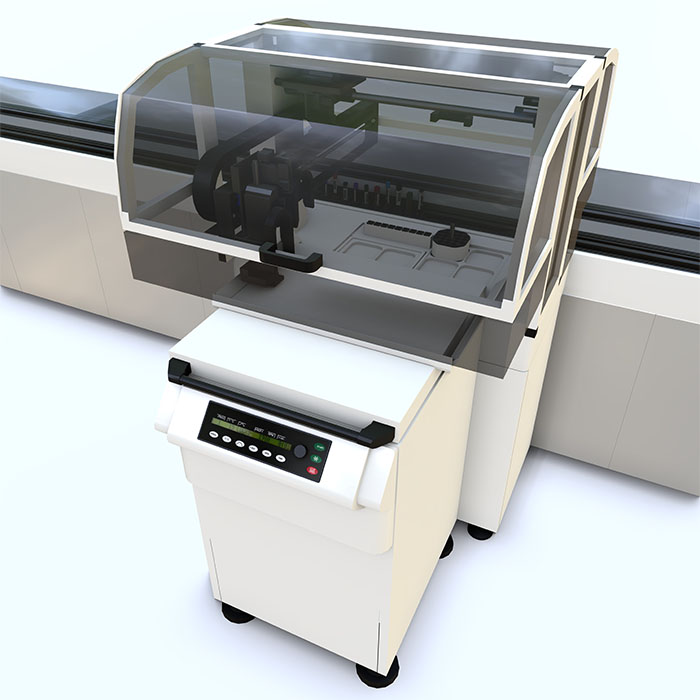

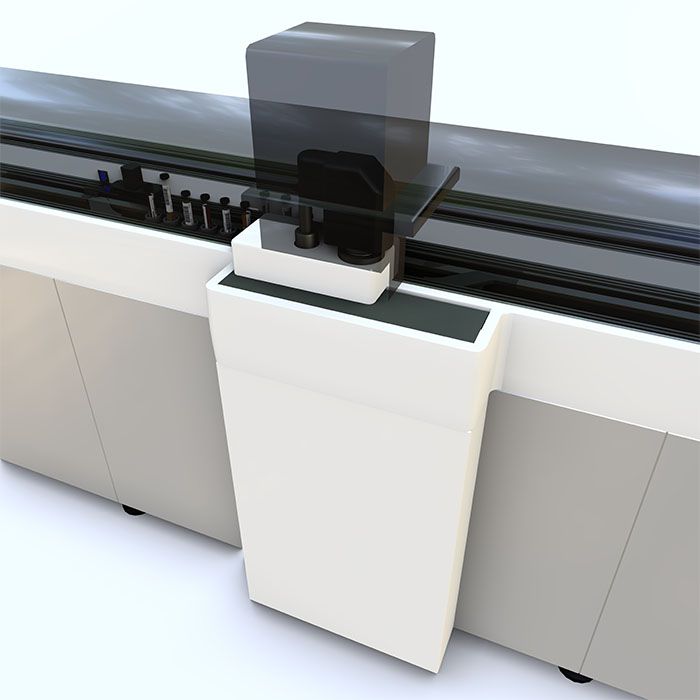

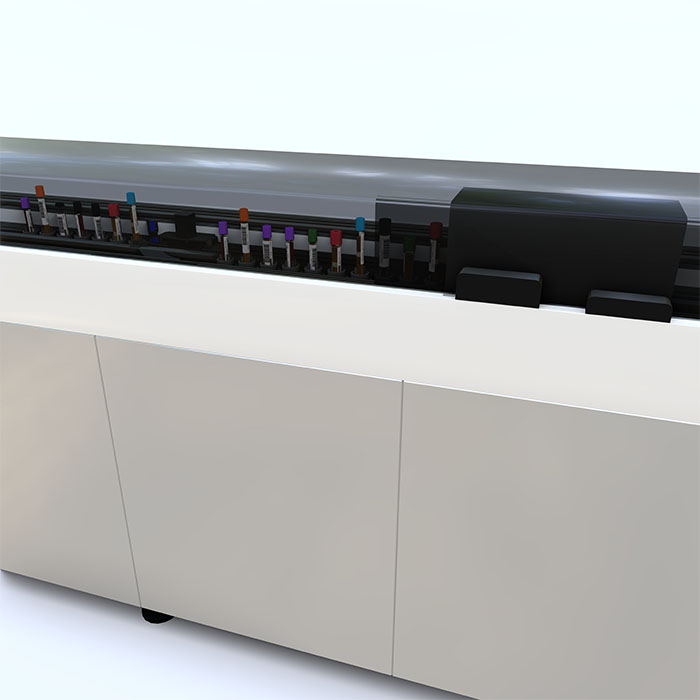

Decapper Module (DCM)

Automates the decapping process of both screw and pressure caps from tubes of different types and sizes, improving operator safety by avoiding manual uncapping. Throughput: up to 800 tubes per hour.

Desealer Module (DSM)

Automates sample preparation by removing the aluminum seals from stored sample tubes, preparing them for re-analysis, reducing dangerous tasks for the operator. Throughput: up to 200 tubes per hour.

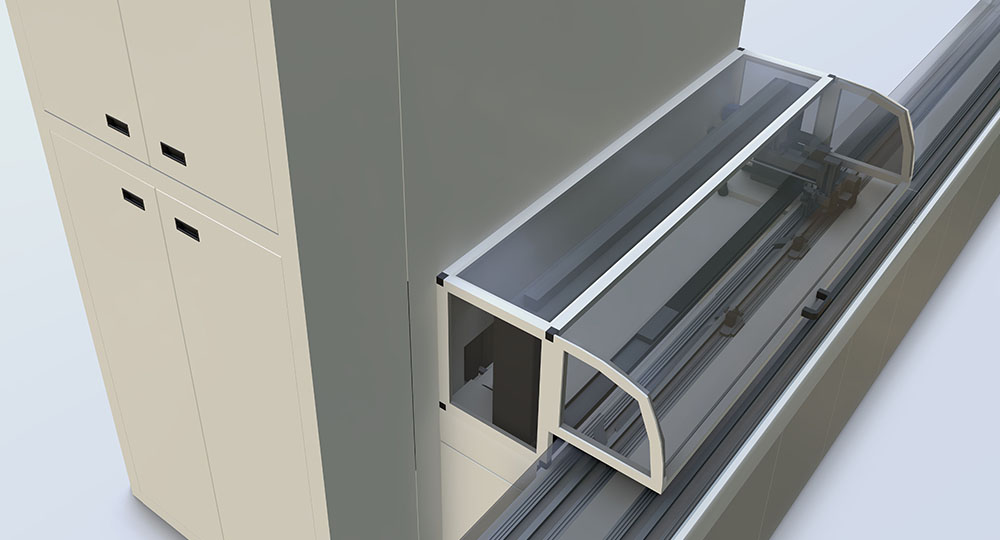

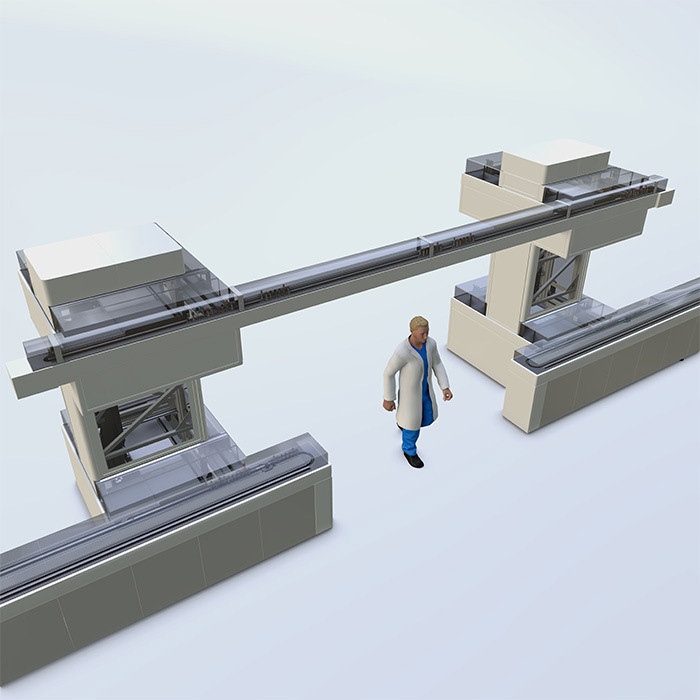

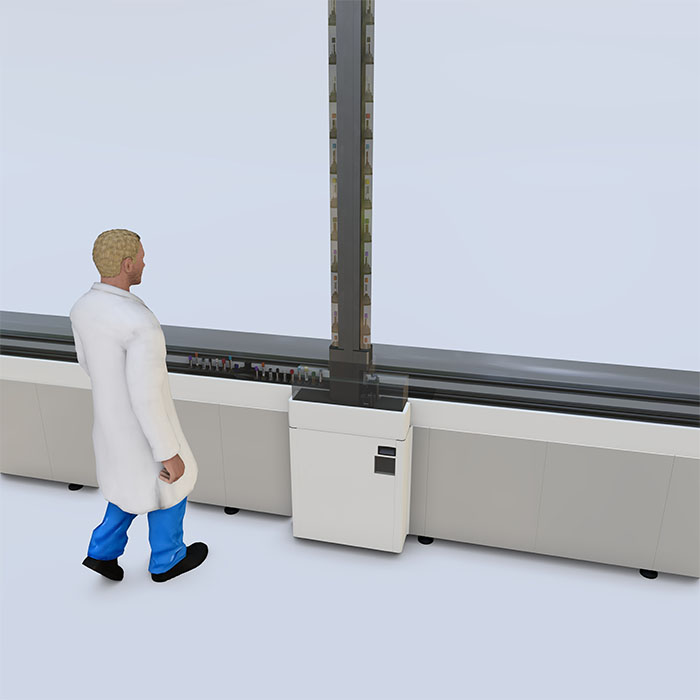

Over-Underpass Module (OUM)

Sample transportation between different automation tracks, to enable the free movement of people throughout the facility. Throughput: up to 10,000 tubes per hour in both directions.

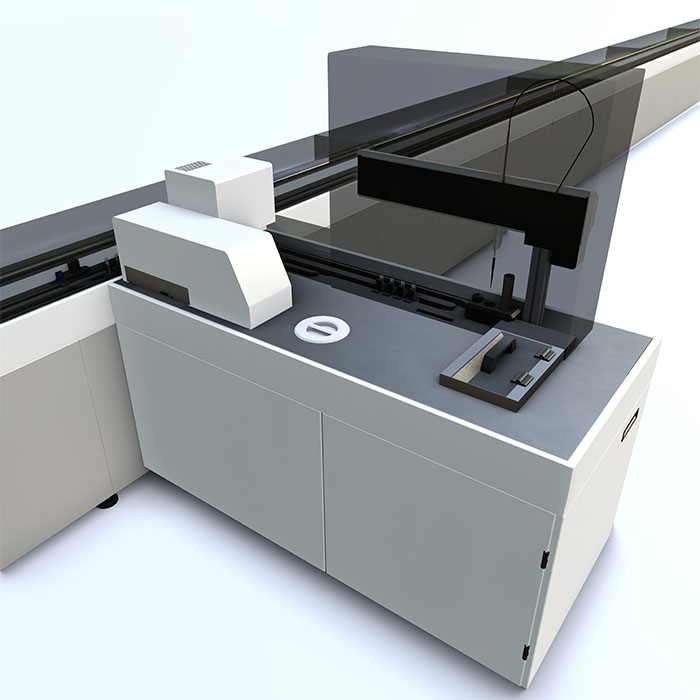

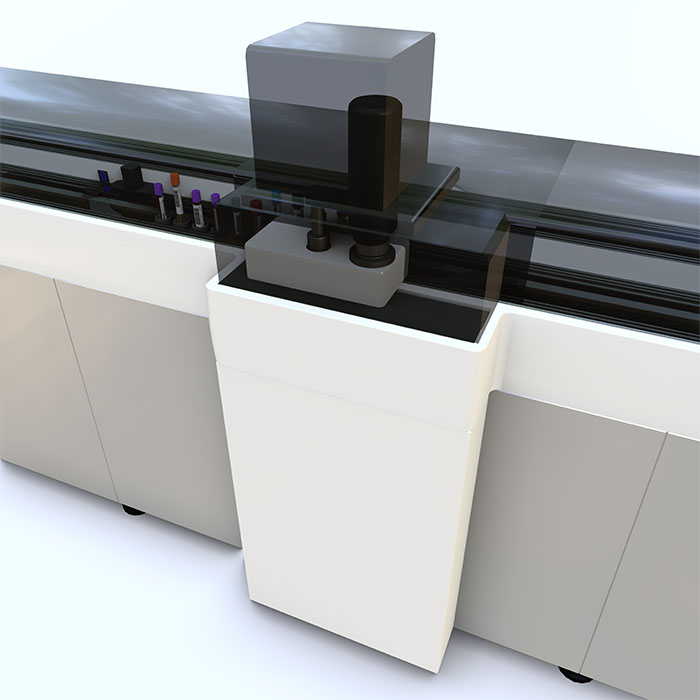

Sample Integrity Module (SIM)

A vision system device performing an early evaluation of serum and plasma volume levels, and HIL (Hemolysis, Lipemia, and Icterus) indexes before analysis, reducing the analyzers’ useless workload. Throughput: up to 650 tubes per hour.

Sample Volume Detection Module (SVD)

Identifies the tube type, detects cap presence, and measures the serum and plasma volume levels with an inbuilt camera, avoiding unnecessary clinical testing. Throughput: up to 800 tubes per hour.

Universal Shaker Module (USH)

Automates the mixing process of blood samples to be homogenized before analysis, preventing damage and hemolysis. The Universal Shaker Module throughput reaches 700 tubes per hour.

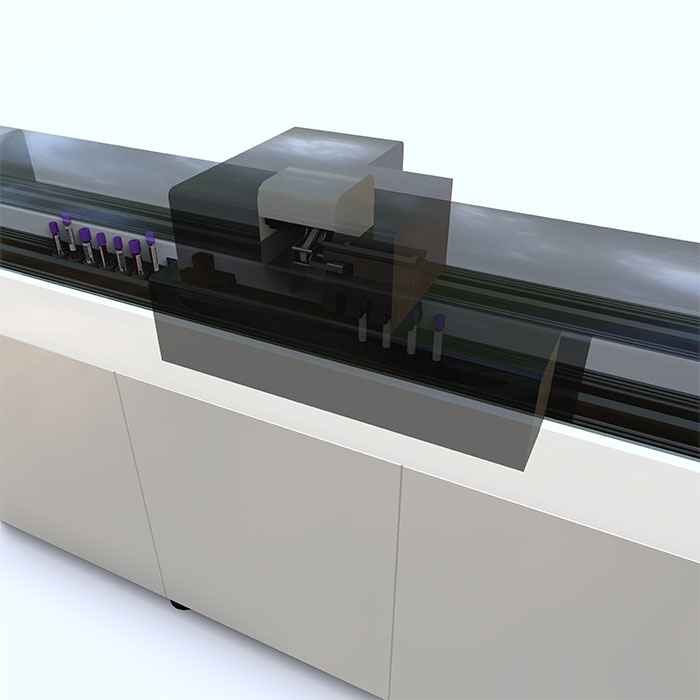

Vertical Transportation Module (VTM)

Allows the connection of two FlexLab™ lab automation systems located on different floors for a full, continuous, and automated workflow. It can be utilized with both uncapped and capped specimens and has a throughput of up to 2,400 tubes/hour.

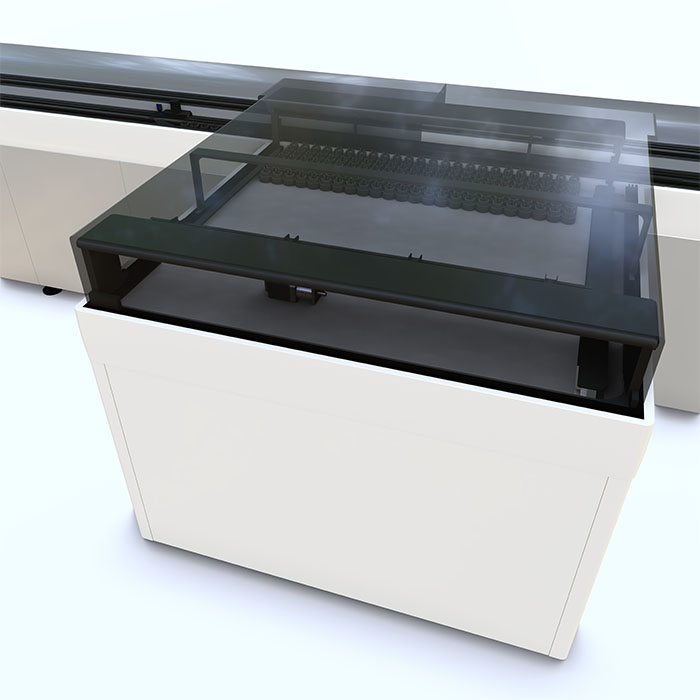

Wide Belt Buffer (WBB)

A sample-carrier collector used to reduce the workload on the lab automation track, by parking non-urgent samples. It can be used as a sample carrier collector or as a sample tube collector. Throughput: up to 800 tubes per hour.