FlexLabTM X – Pre-analytical Modules

After check-in, samples are prepared for analysis

FlexLabTM X’s routes every single sample along its most efficient path through the lab, and prepares it for testing in the assigned analyzers with the following modules:

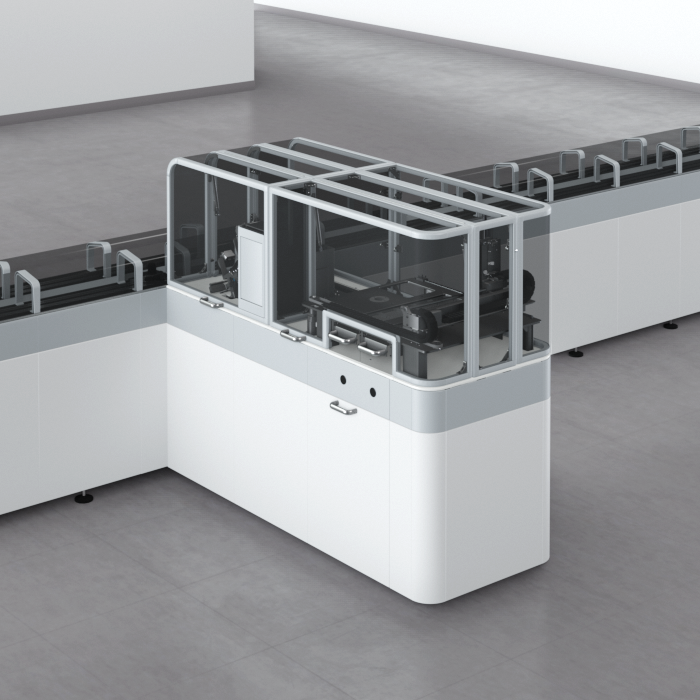

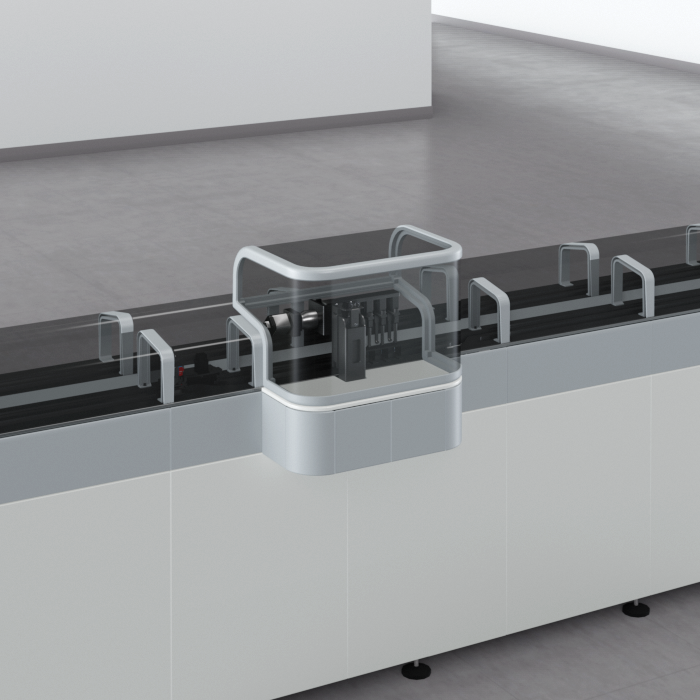

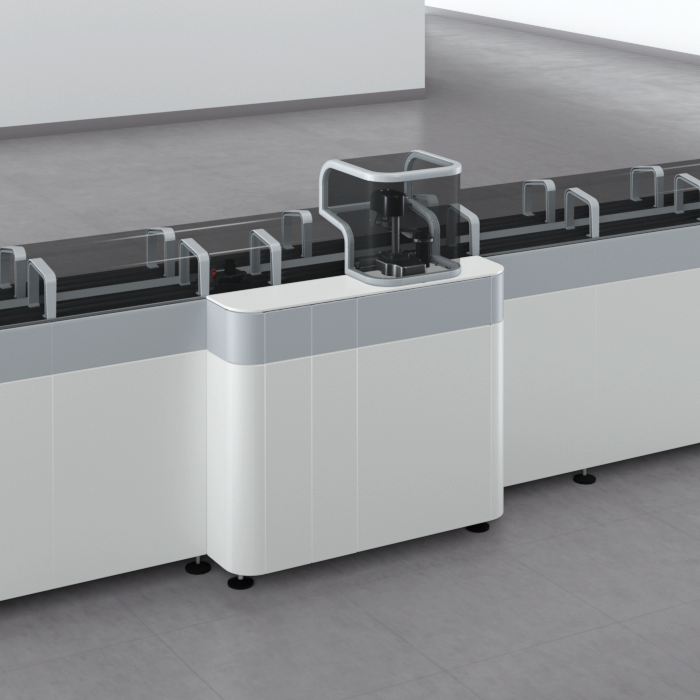

Aliquoter Module (ALX)

For quick preparation of secondary tubes from a primary sample, with a throughput up to 500 tubes/hour. Air displacement technology prevents sample dilution, and on-the-fly consumables loading increases efficiency. The ALX accommodates both non-filter and filter tips for a wide range of applications (e.g. NAT).

Centrifuge Module (CMX)

The module’s integrated Hettich refrigerated centrifuge automates blood sample separation and standardizes the centrifugation process. Its user interface allows for easy customization of the operating parameters to align with specific laboratory guidelines and enables STAT sample prioritization.

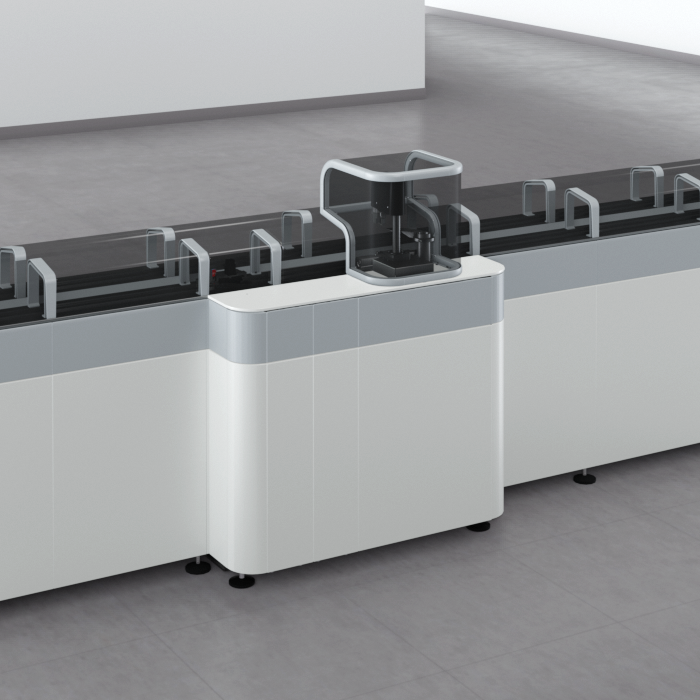

Decapper Module (DCX)

The DCX automates the decapping of sample tubes to increase productivity and improve operator safety by eliminating manual uncapping. The module can handle tubes with their original caps and with original universal caps.

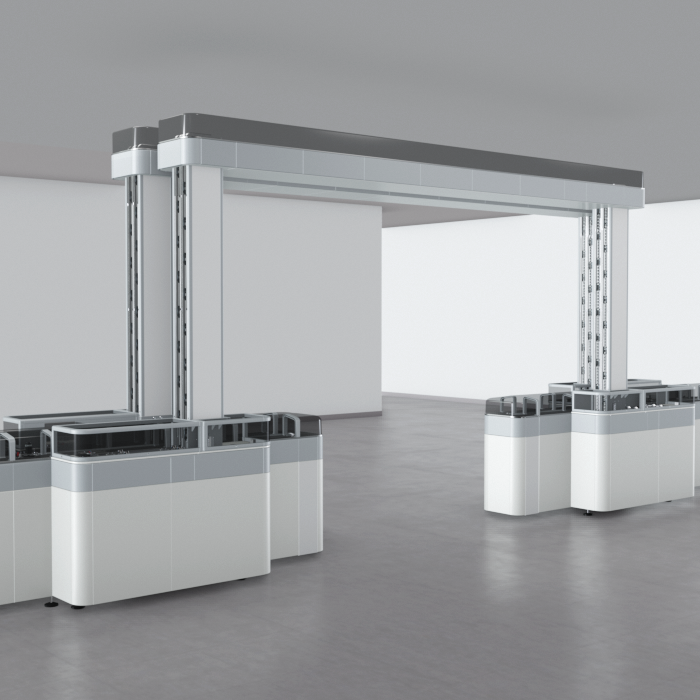

Smart Bridge Module (SBX) and Elevator Module (EMX)

To optimize the use of lab space, these modules connect automation systems located in different rooms or on several floors. Designed to facilitate free staff movement and overcome architectural barriers, they allow very flexible track pathways for lab expansion in three dimensions.

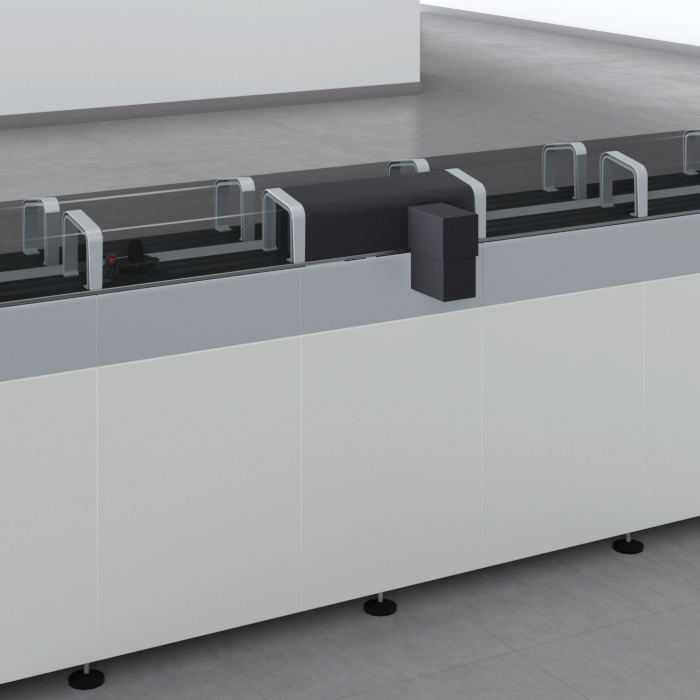

Sample Integrity Module (SIMX)

The Sample Integrity Module detects the volume, upper/lower levels of serum/plasma, and estimates the serum indexes (HIL – Hemolysis, Icterus, Lipemia) to assess the condition of incoming samples, sorting out compromised specimens from the beginning for increased productivity.

Mixer Module (MMX)

The MMX mixes samples shortly before analyses that require homogenization, such as HbA1c, Complete Blood Cells Count, or Erythrocyte Sedimentation Rate, to support high-quality outcomes. Up to four samples can be mixed in parallel, resulting in a throughput of up to 700 tubes/hour.

Desealer Module (DSX)

With the Desealer Module, you can automate the steps of removal of aluminum sealing foils from sample tubes, freeing operator time for other value-added tasks. This allows you to increase productivity and avoid sample spillage and cross-contamination.

Request product information

Interested in finding out how we are redefining lab automation? Complete the form to receive additional information.

"*" indicates required fields