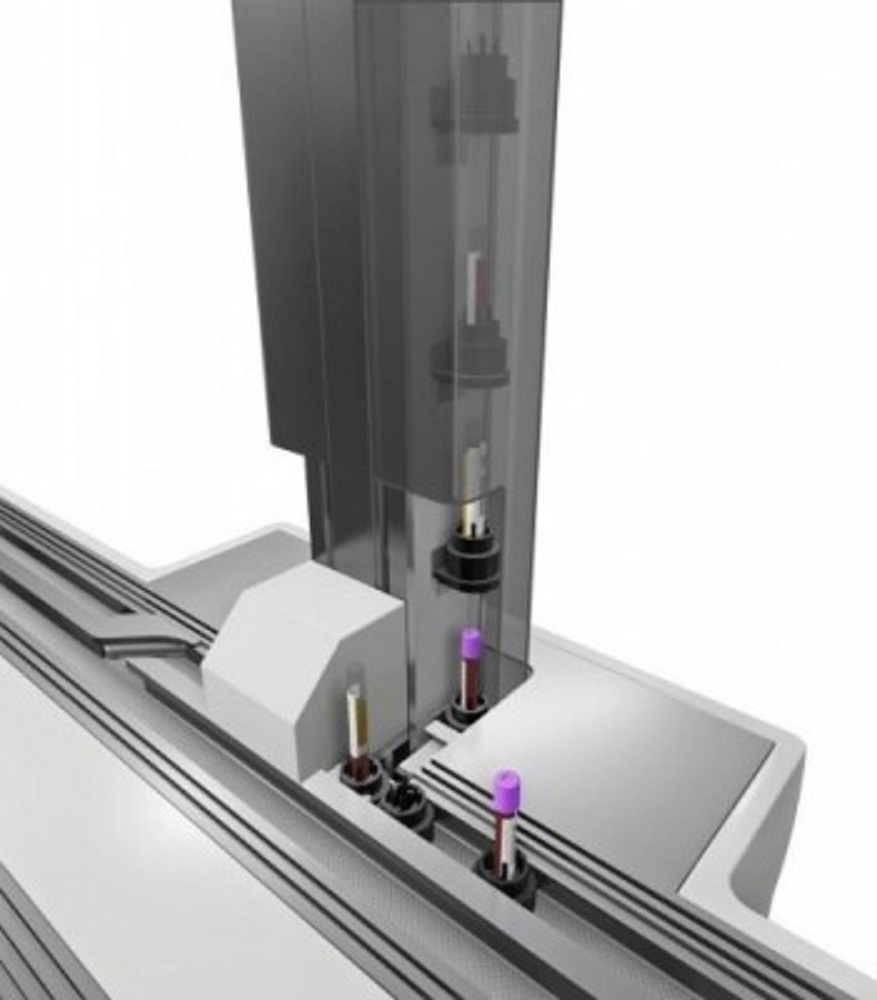

Inpeco Vertical Transportation Module (VTM)

A compelling solution for optimizing the check-in process and increasing workplace efficiency

The Vertical Transportation Module (VTM) allows the connection of two FlexLab™ automation systems located on different floors. The module connects the two systems for a fully, continuous and automated passage of the sample tubes, thus they are not stopped during onload or load movements and transportation activities. The VTM can be utilized with both uncapped and capped specimens and has a throughput up to 2400 tubes/hour.

Key benefits

- Eliminates the need for workers to transport tubes from one floor to another, which leads to improved and consistent TATs with less effort dedicated to repetitive and manual work

- Allows continuous movement of the tubes, enabling 100% sample traceability

- Prevents exposure to hazard samples and avoids cross contamination

Optimizes the laboratory footprint, allowing multiple automation tracks to connect on different floors thus allowing more practical and efficient layouts.

How it works

From the main track line, the tubes are routed into the internal buffer of the VTM, where the carriers are then validated before making the seamless transfer onto the vertical track. Once they arrive on the new floor, the carriers exit onto the return lane, are validated, and then enter onto the secondary track. The result: carriers and tubes are routed seamlessly and without being touched between two automation systems

Viollier User case

In Switzerland, our customer Viollier successfully implemented the VTM in their laboratory. Read their story and learn how they took advantage of the VTM.

VTM is currently available on FlexLab systems for high throughput.

Are you interested in the VTM and how it can be implemented in your laboratory?