Automation in the lab: there is still a lot to be discovered

What makes Inpeco FlexLabTM unique in the Total Lab Automation (TLA) segment?

Clinical analysis has been using automation for over 50 years to significantly increase productivity and improve the quality of the final results. In this transformation, the most visible component (hardware) plays a minor role when compared with the evolution of the software component, which has reached extremely high levels of performance and sophistication, in recent years.

Definition of TLA

Since 1995 (when Inpeco introduced the first prototype, at the AACC Conference), ‘Total Laboratory Automation’ (TLA) is defined as the automatic processing of the entire flow of the analysis, from sample load to its retention and subsequent elimination, thanks to the physical and logical connection to the analyzers, without human intervention, in complete safety and traceability. Unlike Task Targeted Automation (TTA, i.e. automation of specific routine tasks), TLA offers the real continuum of the testing process by connecting tasks and specialties, thus eliminating human manipulation of specimens.

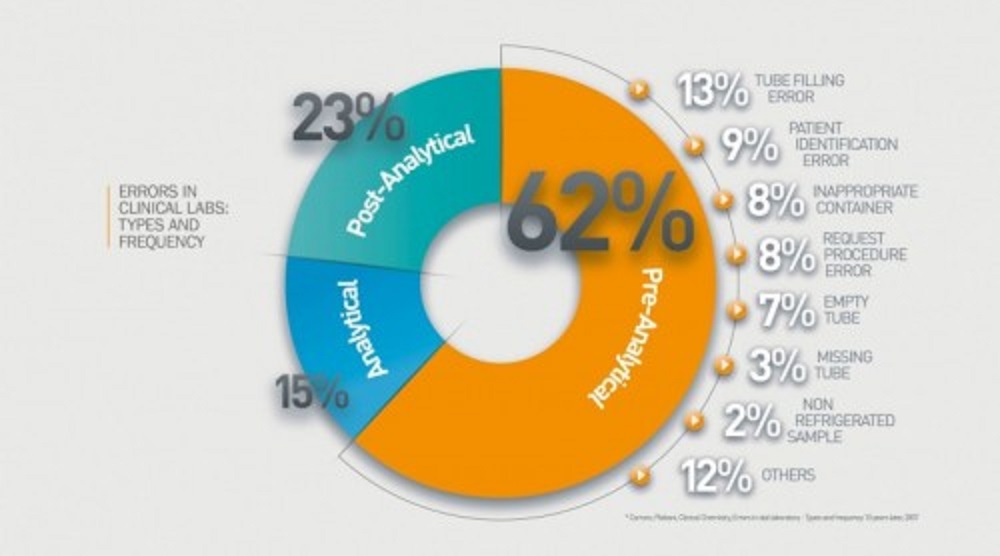

Errors in clinical labs

Literature estimates that laboratory tests contain an error rate of approximately 0.5%, which, when viewed on a global scale, becomes catastrophic despite seeming like a low number.

- switching test tubes,

- incorrect procedures,

- loss of samples:

these cases are the most common, and even when there are no critical outcomes, they require repeating the tests, resulting in an increase in costs.

(1) Carraro, Plebani – Errors in a stat laboratory: types and frequencies 10 years later. Clin Chem. 2007 July

Benefits of a TLA solution

The main benefits of a TLA System are well known and scientific literature offers many pieces of evidence, through different angles.

- It allows the reduction of outliers by ensuring a turnaround time (TAT) within a limited range, for optimum job scheduling.

- Therefore, there is more valuable free time for the operators, who can focus on the interpretation of the results produced – after all, this is the main topic in which they specialized their studies and which most directly impacts the patient waiting for the report.

- With automation, labs can carry out tests even during night/other closing times, when human resources are more difficult and costly to find.

- The positive impact on laboratory operators also includes higher safety levels, given the reduced direct contact with potentially infective biological samples.

- Diagnostic laboratories are progressively consolidating, resulting in an increase in daily test volumes. Automation with efficient and traceable processes is the only way to guarantee these volumes, as it offers concrete possibilities of scalability that evolve with the needs.

The uniqueness of Inpeco’s TLA FlexLabTM system

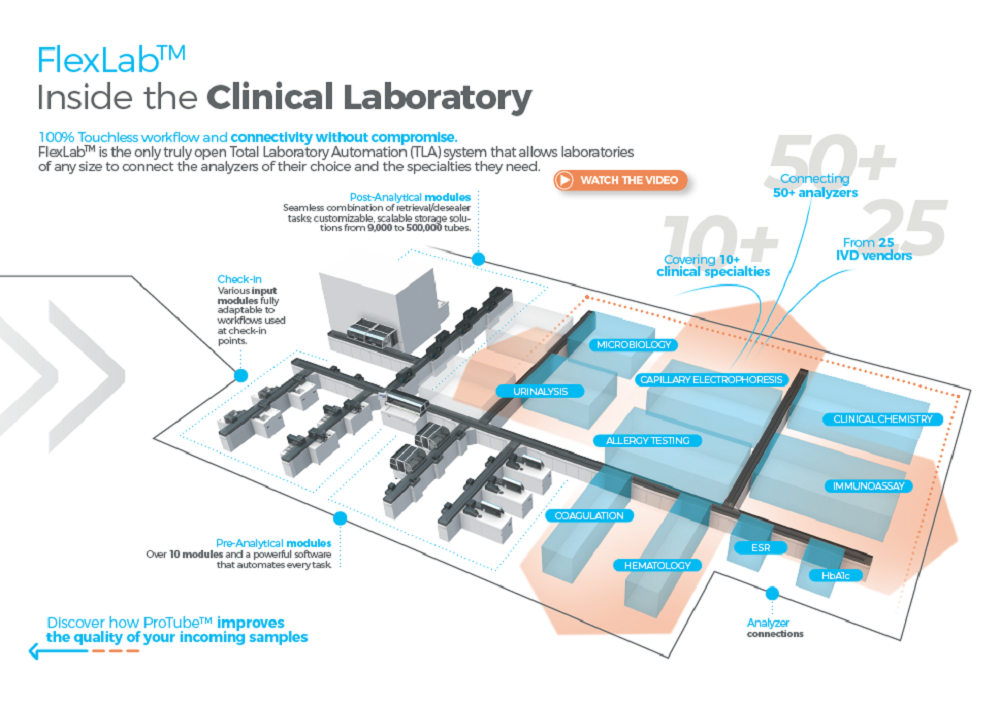

FlexLab is the ideal open ‘backbone’ that can connect all routine lab’s tasks with the widest range of analyzers, for most of the clinical specialties. Its wide range of automation modules makes it possible to automatically perform all the routine phases before, during, and after the analytical phase, without interruption and thus enabling total sample traceability.

Moreover, the Inpeco track can work with over 50 different analyzers of all major specialties, including microbiology. This ‘open connectivity’ of FlexLabTM architecture allows track scalability, as the needs of the lab evolve, e.g. in case of growth or changes in the set of analyzers installed, so that the investment made by the lab is safe for years to come.

Unique in its kind, Inpeco automation can support very complex installations; the system can manage extremely high workloads, above 10,000 samples per hour, and has vertical transportation modules for the sites that are distributed on different floors.

Inpeco has unparalleled expertise in the TLA segment, collected and built inside the 2000 labs that are using its solutions (also under the trademarks Siemens Aptio Automation and Abbott Aa3600), in over 70 countries, all over the worlds.

From very complex installations (eg Quest lab in Marlborough, US, or Hermes Pardini in Brazil) to more simple but original ones (eg MSK in NYCity or Furst Lab, Norway), the FlexLab open track offers innovative automation solutions to the laboratories that want to differentiate their clinical outcomes.

Traceability outside the lab

Following its mission to eliminate human error in diagnostic processes, Inpeco has introduced traceability solutions from the very origin of the sample, i.e. the collection point, where the correct matching between patient id & test tube is critical since most laboratory errors occur in this phase.

Here, the ProTubeTM system, used in front of the patient at the time of withdrawal, guarantees the correctness of the container used, of its labeling, and – if used with any biometric reader device – of the identity of the patient. It’s a sort of pre-pre-analytical ‘module’ that integrates perfectly with the workflow inside the lab rooms. Thanks to this additional ‘module’, Inpeco’s solutions will allow the Clinical laboratory to get closer to the “zero errors” goal, a mandatory milestone for those professionals working in a sector so crucial for our lives.

Looking for more details?